This hydraulic gear pump operates on the principle of positive displacement.

As the gears rotate, they create a sealed chamber between them, which gradually increases in size. This chamber draws in hydraulic fluid from the inlet port and then forces it out through the outlet port under pressure. The continuous rotation of the gears ensures a consistent flow of hydraulic fluid, making it suitable for various hydraulic systems.

Construction Equipment: These pumps are often employed in bulldozers, excavators, and loaders to power various hydraulic functions like lifting, digging, and steering.

Agriculture: They are used in tractors and agricultural machinery for functions such as raising and lowering implements, as well as controlling steering and brakes.

Material Handling: Hydraulic gear pumps are essential in forklifts and conveyor systems for smooth material handling operations.

Automotive: They are utilized in power steering systems, automatic transmissions, and other automotive applications to control various hydraulic functions.

Manufacturing: Hydraulic gear pumps are employed in manufacturing machinery, including presses, injection molding machines, and metal forming equipment.

Marine: In boats and ships, these pumps can be found in hydraulic steering systems, winches, and other marine applications.

Key Features:

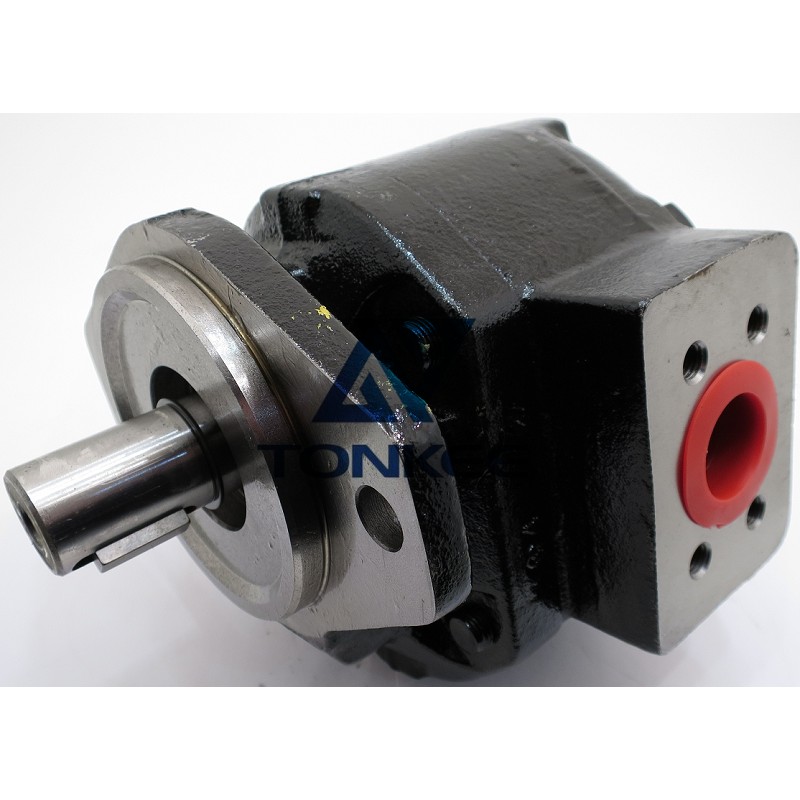

Compact Design: The 5H1 40136DB pump is known for its space-saving design, making it suitable for installations where space is limited.

High Efficiency: It offers excellent efficiency, ensuring minimal energy loss and reduced heat generation during operation.

Reliability: Due to its positive displacement design, this hydraulic gear pump is highly reliable and capable of providing a consistent flow and pressure.

Low Noise: Modern hydraulic gear pumps are engineered to operate with reduced noise levels, making them suitable for noise-sensitive environments.

Easy Maintenance: Routine maintenance is relatively straightforward, with easy access to internal components for inspection and repair.