Flow Rate: The 3PL250ASSSAN pump is designed to deliver a consistent and precise flow of hydraulic fluid.

Its flow rate can vary depending on the specific model and configuration, making it adaptable to a wide range of hydraulic systems.

Pressure Rating: This hydraulic gear pump is capable of generating high pressures, making it suitable for applications that require substantial force. The pressure rating typically varies across models, but it is known for its ability to handle demanding tasks.

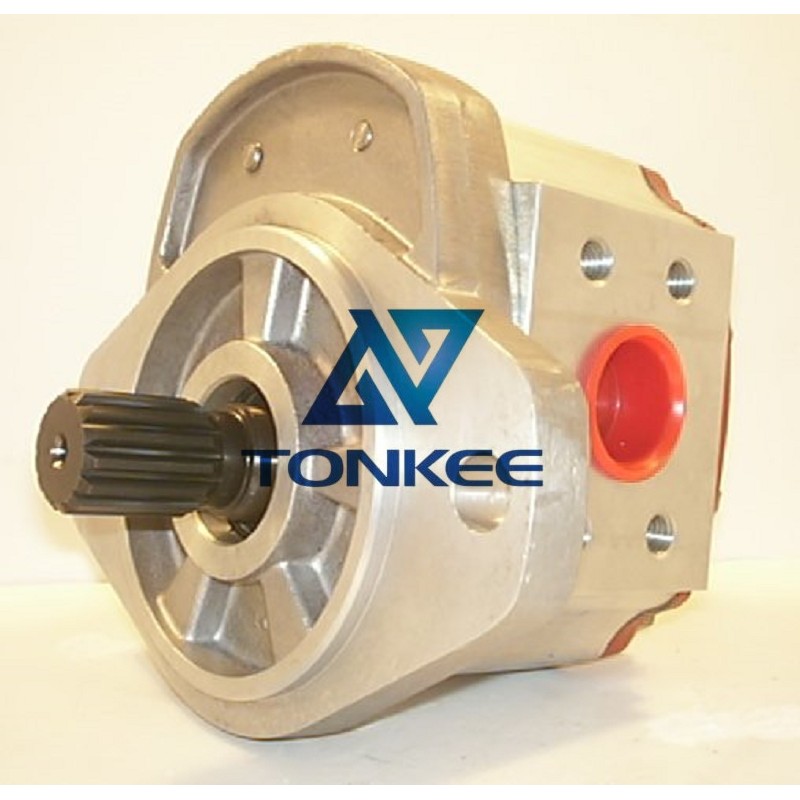

Compact Design: One of the notable characteristics of this pump is its compact design. It is engineered to occupy minimal space, which is particularly advantageous for installations with limited room or where space optimization is crucial.

Durability: The 3PL250ASSSAN pump is built to last, featuring robust materials and precise machining. It can endure the rigors of industrial environments, including exposure to dust, moisture, and varying temperatures.

Efficiency: Hydraulic gear pumps are renowned for their high efficiency. They minimize energy losses and provide a steady flow of hydraulic fluid, resulting in improved system performance and reduced operating costs.

Low Noise: These pumps are designed to operate quietly, making them suitable for applications in noise-sensitive environments or where noise pollution is a concern.

Working Principle:

The 3PL250ASSSAN hydraulic gear pump operates based on the principle of positive displacement.

It consists of two meshing gears – a driver gear and a driven gear – housed within a pump casing. As the driver gear rotates, it creates a void in the pump's inlet, which allows hydraulic fluid to enter. As the gears continue to rotate, they trap the fluid in between the gear teeth and force it towards the pump's outlet. This action results in a continuous flow of hydraulic fluid, providing the required pressure and volume for the system.

Construction Machinery: These pumps power the hydraulic systems of excavators, bulldozers, and loaders, enabling precise control of heavy equipment.

Agricultural Equipment: They are employed in tractors, combine harvesters, and other farm machinery for tasks like lifting, tilting, and steering.

Material Handling: Hydraulic gear pumps are integral to forklifts, cranes, and conveyor systems, facilitating the efficient movement of materials.

Automotive Industry: They play a crucial role in power steering systems, transmission systems, and brake systems in automobiles.

Manufacturing Equipment: These pumps are used in injection molding machines, press brakes, and other industrial equipment.