The 5CAP330SS is a type of hydraulic gear pump, a positive displacement pump that operates by meshing two gears to create a fluid flow.

It is often used in hydraulic systems to transfer hydraulic fluid and generate pressure for various functions.

Flow Rate:

This hydraulic gear pump has a rated flow rate of [specific flow rate] liters per minute (LPM). This flow rate indicates the volume of hydraulic fluid it can deliver in a minute, which is a crucial parameter for determining its performance in a hydraulic system.

Pressure Rating:

The 5CAP330SS is designed to handle a maximum hydraulic pressure of [specific pressure rating] PSI (pounds per square inch). The pressure rating is essential for ensuring that the pump can withstand the pressure generated within the hydraulic system without any damage.

Construction Material:

The pump housing and gears are typically constructed from high-quality materials like cast iron or steel. These materials offer durability and corrosion resistance, ensuring a long service life, even in harsh industrial environments.

Mounting Configuration:

The 5CAP330SS can be configured for various mounting options, including flange or foot mounting. This flexibility allows for easy integration into different hydraulic systems.

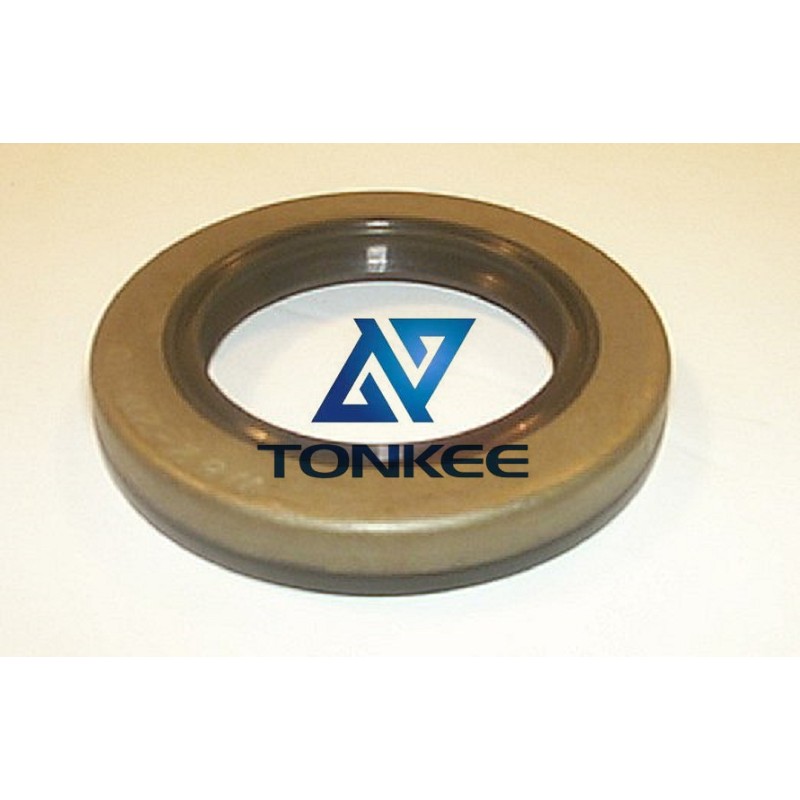

Shaft Seal:

A shaft seal is crucial to prevent hydraulic fluid leakage from the pump.

The 5CAP330SS is equipped with a high-quality shaft seal that ensures minimal leakage, enhancing its overall efficiency.

Rotation Direction:

This hydraulic gear pump is designed to operate in a specific rotational direction. It is important to ensure that the pump is installed correctly to ensure proper fluid flow and prevent damage.

Temperature Range:

The 5CAP330SS is capable of operating within a specified temperature range, typically between [specific temperature range] degrees Celsius. It is important to operate the pump within this range to maintain optimal performance and prevent overheating or fluid thickening.

Fluid Compatibility:

Hydraulic gear pumps like the 5CAP330SS are compatible with a wide range of hydraulic fluids, including hydraulic oils, synthetic fluids, and certain types of coolants. It is essential to use the appropriate fluid as specified in the manufacturer's guidelines to ensure reliable performance.