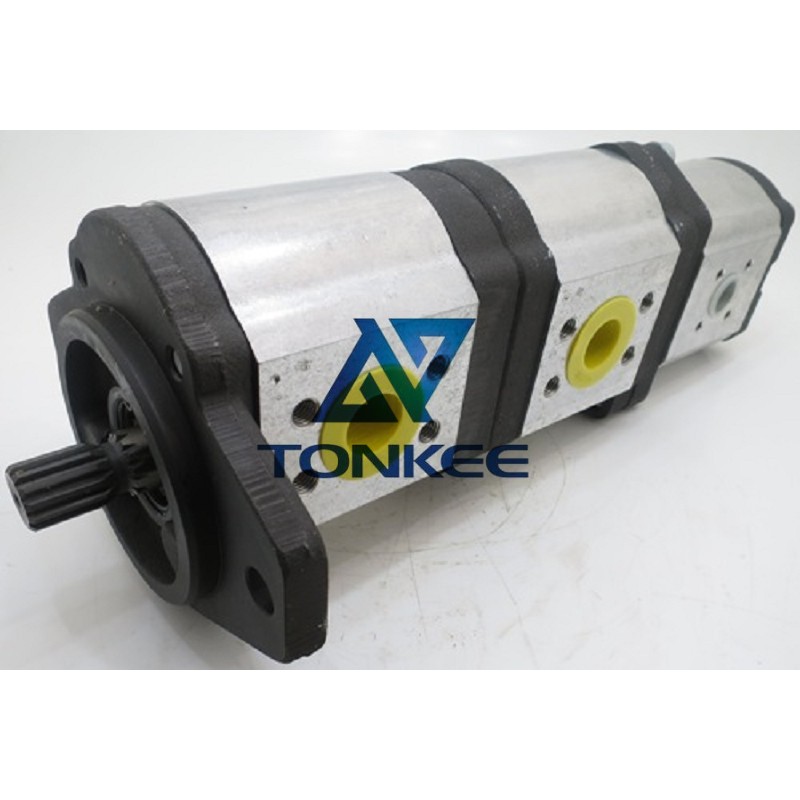

The 5B3 37511DEM hydraulic gear pump features a compact and robust design, making it suitable for a wide range of applications.

It is constructed using high-quality materials to ensure long-lasting performance even in demanding environments. The pump is primarily made up of two meshing gears – the driving gear and the driven gear. These gears rotate in opposite directions, creating a tight seal between them, which is crucial for efficient fluid displacement.

Flow Rate and Pressure:

This hydraulic gear pump is capable of delivering a consistent flow of hydraulic fluid. The flow rate typically ranges from 5 to 15 gallons per minute (GPM), although specific flow rates may vary depending on the application and configuration. Additionally, the pump can generate hydraulic pressures in the range of 1,000 to 3,000 PSI (pounds per square inch), allowing it to handle various tasks that require substantial force.

Versatility:

One of the standout features of the 5B3 37511DEM pump is its versatility. It can be employed in a wide array of industries, including agriculture, construction, manufacturing, and more. It is commonly used to power hydraulic cylinders, motors, and other hydraulic actuators. Its ability to work with different hydraulic fluids and adapt to various operating conditions makes it a valuable component for many hydraulic systems.

Efficiency and Reliability:

Efficiency is a crucial factor in hydraulic systems, as it directly impacts energy consumption and overall performance.

The 5B3 37511DEM hydraulic gear pump is designed with efficiency in mind. Its gear mechanism ensures minimal internal leakage, leading to improved overall efficiency. This efficiency translates to less heat generation and reduced energy consumption, which can result in cost savings and extended equipment lifespan. Furthermore, the pump's durable construction and precision engineering contribute to its reliability, minimizing downtime and maintenance costs.

Installation and Maintenance:

Installing and maintaining the 5B3 37511DEM hydraulic gear pump is relatively straightforward. It typically comes with mounting options for easy integration into hydraulic systems. Routine maintenance involves checking for leaks, inspecting the gears for wear, and ensuring proper lubrication. The simplicity of its design makes it easier to troubleshoot and repair, reducing downtime and associated costs.

Environmental Considerations:

In today's environmentally conscious world, hydraulic components must meet certain standards. The 5B3 37511DEM pump is designed to minimize environmental impact by reducing fluid leaks and energy consumption. It is also compatible with various eco-friendly hydraulic fluids, making it a responsible choice for businesses seeking to reduce their carbon footprint.