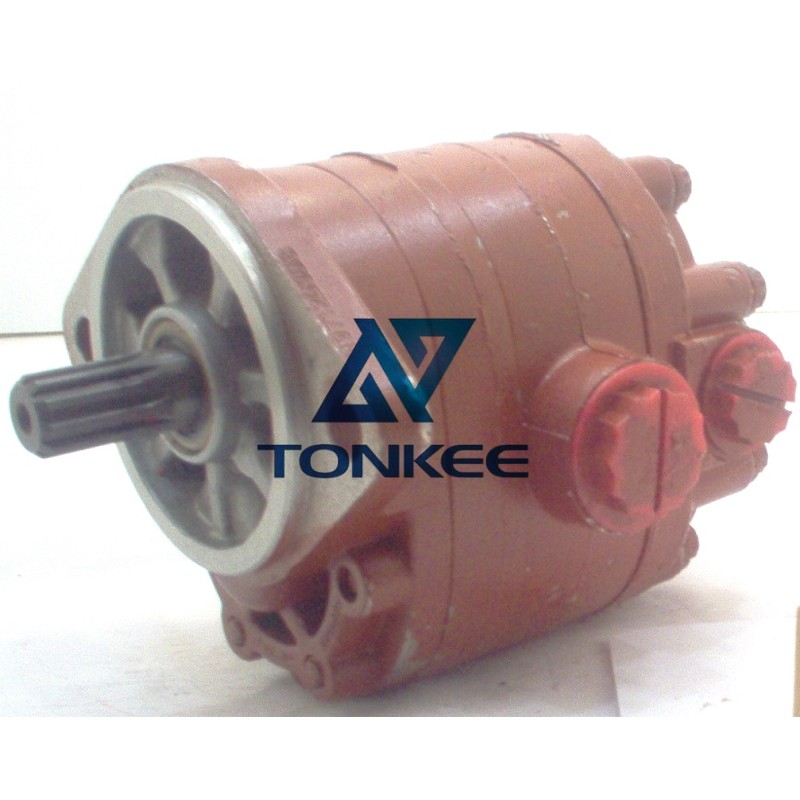

This hydraulic gear pump is designed with precision engineering to ensure durability, reliability, and efficiency.

It consists of several key components, including a housing or casing, gears, and various ports for fluid inlet and outlet. The pump operates on the principle of positive displacement, which means that it delivers a fixed amount of fluid per rotation of the gears.

The gears inside the pump are typically helical or spur gears, and they are precisely machined to fit together with minimal clearance. This close tolerance ensures minimal leakage and efficient operation. The gears rotate within the pump housing, trapping hydraulic fluid between their teeth and the housing walls. As the gears rotate, they create a pressure differential that forces the fluid to flow from the inlet to the outlet, generating hydraulic power.

Specifications:

The 5C2 24385RAP hydraulic gear pump has specific specifications that make it suitable for a wide range of hydraulic applications. These specifications include:

Flow Rate: The flow rate of the pump determines how much hydraulic fluid it can deliver per unit of time. This pump's flow rate is optimized for its intended use, ensuring adequate fluid supply to the hydraulic system.

Pressure Rating: Hydraulic systems often operate under high pressures.

This pump is designed to handle specific pressure ranges, ensuring that it can provide the required power without failing under pressure.

Material: The pump is typically constructed from high-quality materials like cast iron or aluminum, which offer a balance of strength and weight. The choice of material also affects the pump's resistance to corrosion and wear.

Mounting Options: Different applications may require various mounting configurations. This pump may have different mounting options, such as flange or bracket mounting, to accommodate different installation requirements.

Sealing: Proper sealing is crucial to prevent leakage and ensure the pump's efficiency. This hydraulic gear pump is equipped with seals and gaskets designed to withstand hydraulic fluid pressure and temperature variations.

Port Size: The size of the inlet and outlet ports determines the flow capacity and compatibility with other hydraulic system components. Port sizes are specified to ensure proper fluid connections.

Drive Configuration: This pump may be configured to be driven by an electric motor, internal combustion engine, or other power sources, depending on the application's needs.