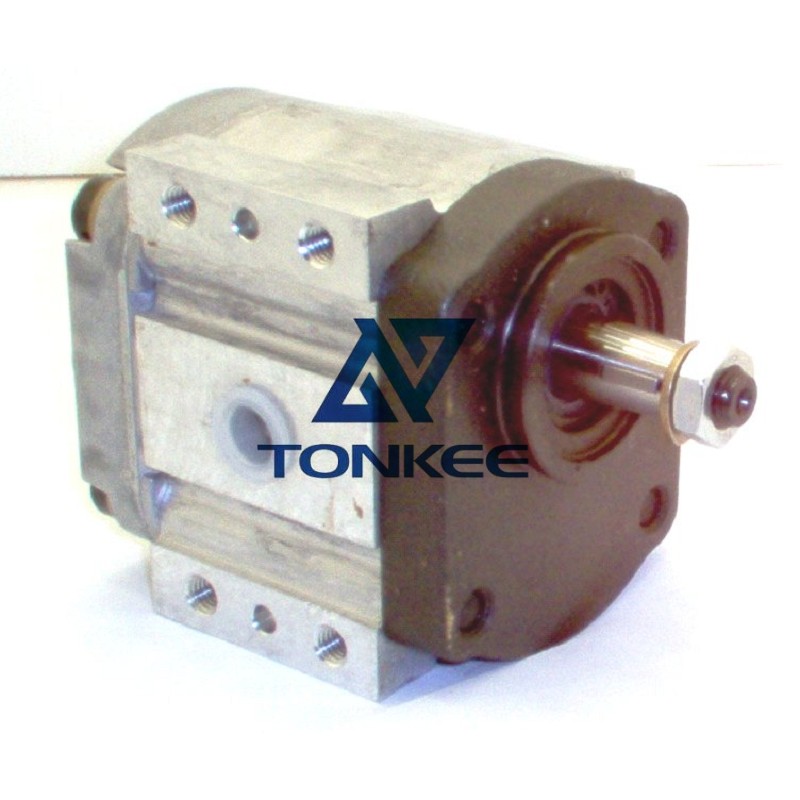

The 5B1 40050MF is a hydraulic gear pump, which means it utilizes a pair of meshing gears to generate fluid flow.

It is known for its simplicity and reliability. This pump is typically made from high-quality materials to withstand the rigors of industrial use.

Flow Rate:

One of the most crucial specifications of any hydraulic pump is its flow rate, which is measured in liters per minute (LPM) or gallons per minute (GPM). The 5B1 40050MF hydraulic gear pump has a flow rate of 50 LPM (approximately 13 GPM). This indicates the volume of hydraulic fluid it can transfer per minute.

Another vital specification is the pressure rating, which determines the maximum pressure the pump can generate. The 5B1 40050MF typically has a pressure rating of around 2500 PSI (pounds per square inch) or 172.4 bar. This pressure capability makes it suitable for various applications where high-pressure hydraulic systems are required.

Size and Mounting:

The physical dimensions of the 5B1 40050MF hydraulic gear pump play a significant role in its compatibility with different equipment. These pumps are available in various sizes and mounting configurations to accommodate specific space constraints and application requirements.

Shaft Type:

The pump may come with different shaft options, such as splined, keyed, or tapered shafts, depending on the compatibility with the driven component or motor.

Direction of Rotation:

Hydraulic gear pumps like the 5B1 40050MF can be designed to rotate in either clockwise or counterclockwise directions.

The direction of rotation is essential for the correct operation of the hydraulic system it is part of.

Seal Type:

The choice of seals is crucial to prevent leakage and maintain the integrity of the hydraulic system. The 5B1 40050MF pump may come with different seal options, including lip seals, viton seals, or other specialized seals for specific applications.

Material Compatibility:

The pump's construction materials must be compatible with the hydraulic fluid being used. The 5B1 40050MF is typically constructed using materials like cast iron or aluminum, which are known for their durability and resistance to corrosion.

Efficiency and Noise Level:

Efficiency is a critical consideration for hydraulic pumps, as it can affect the overall energy consumption of the hydraulic system. Additionally, noise level is an important factor in applications where noise reduction is a priority. Manufacturers often provide efficiency and noise level specifications for their pumps.