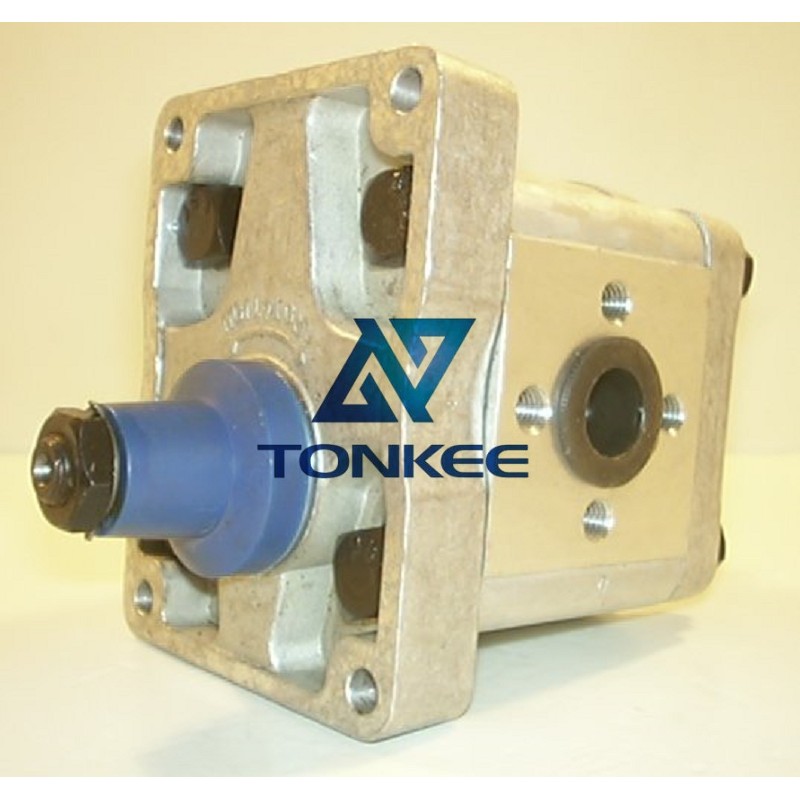

At its core, the GP2C25XT is a positive displacement hydraulic gear pump.

It operates on the principle of using two interlocking gears to create hydraulic pressure and fluid flow. These gears, typically made of high-quality materials like hardened steel, are housed within a robust casing designed to contain hydraulic fluid under pressure. The rotation of the gears generates suction on one side and discharge on the other, facilitating the movement of hydraulic fluid through the system.

One of the standout features of the GP2C25XT is its remarkable efficiency. It excels at converting mechanical energy from an external power source, such as an electric motor or internal combustion engine, into hydraulic power efficiently. This efficiency is a significant advantage, particularly in applications where energy conservation and performance optimization are critical. Minimizing energy wastage and heat generation helps maintain the overall effectiveness of hydraulic systems.

The GP2C25XT boasts impressive performance specifications, making it suitable for a wide range of applications. Its flow rate typically falls within the range of 1 to 30 gallons per minute (GPM), allowing it to handle various hydraulic fluid requirements. The maximum pressure it can generate varies but typically falls in the range of 1,000 to 3,000 pounds per square inch (PSI). These performance characteristics make it a versatile choice for a broad spectrum of applications, from smaller machinery to heavy-duty industrial equipment.

Durability and reliability are fundamental attributes of the GP2C25XT.

It is engineered to endure challenging operating conditions, including high temperatures, extreme pressures, and the presence of abrasive contaminants that are common in hydraulic systems. This robust construction ensures an extended service life, minimizing maintenance expenses and equipment downtime.

Installation and maintenance of the GP2C25XT are relatively straightforward, contributing to its popularity in various applications. Routine maintenance typically includes inspecting the gears for signs of wear, checking for leaks, and ensuring the correct alignment of the pump within the hydraulic system. Proper lubrication is essential to reduce friction between the gears and extend their lifespan.

The GP2C25XT's adaptability is another key feature. It can be seamlessly integrated into various hydraulic systems, such as those used in agricultural machinery, construction equipment, material handling systems, and industrial manufacturing processes. Its adaptability stems from the availability of different configurations, including single and multiple stage versions, allowing it to cater to a wide range of flow rates and pressure requirements.